Electrostatic oil mist recovery device

Keywords:

Classification:

Details

Product Features

01

Efficient and durable

02

energy saving

03

Use safety

04

easy maintenance

Product advantages

The filtration efficiency is efficient and durable, especially suitable for purifying a large number of fine fumes generated by pure oil cutting.

● The energy consumption of the equipment is much lower than that of other similar equipment, and only 1/5 of the electricity consumption of other equivalent equipment.

● Equipment only needs daily cleaning and maintenance, long-term application without consumables, no subsequent use cost.

● The capture efficiency is as high as 95% and the purification efficiency is more than 99%.

● The overall solution to the workshop oil mist, smoke and other issues, greatly improve the working environment of workers without another negative pressure fan.

●In order to ensure the purification efficiency of the equipment, the equipment should work in a negative wind pressure state, that is, the fan must be located behind the equipment; the fan inlet and outlet should be installed with soft connection

Scope of application

The intelligent and efficient oil mist recovery device produced by Hebei Ruiao Machine Parts Manufacturing Co., Ltd. is suitable for oil mist purification and filtration of general lathes, milling machines, grinders, discharge processing machines, die casting machines, CNC machine tools and other machine tools or cleaning equipment.

Working principle

This product uses mechanical purification and electrostatic purification dual role. Dirty air first enters the primary unit-purification rectifier chamber, and gravity inertial purification technology is adopted. The special structure in the chamber gradually classifies and physically separates large particle size pollutants and equalizes rectification. The remaining small particle size pollutants enter the secondary device-a high-voltage electrostatic field. There are two stages in the electrostatic field. The first stage is an ionizer. The strong electric field charges the particles and becomes charged particles. These charged particles are immediately adsorbed by the collection electrode after reaching the second dust collector. Finally, through the filter grille, clean air out of the outdoor.

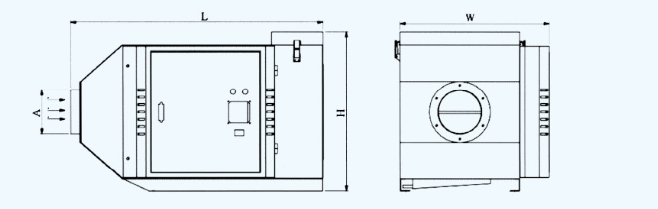

Equipment outline

Inquiry

China

China English

English