Wall machine tool protective cover

Keywords:

Classification:

Details

Product Introduction

The wall-type machine tool protective cover, also known as the universal protective cover, is a protective facility suitable for machining centers manufactured by Riao Company. This series is divided into steel plate wall-type protective cover and armor wall-type protective cover, which can follow the horizontal, vertical and universal movement of the machining center in the working process, thus fully protecting the machine tool. hebei rio is a professional manufacturer of protective cover.

Product Structure

Type: According to the scope of use of the machining center, the wall-type protective cover can be roughly divided into two types: steel plate type and armor type; the former is mostly used in casting processing occasions, while the latter is mostly used for cutting fluid with large stroke and fast speed. Machining center machine tool.

Product Features

01

High precision and fast speed

02

High temperature resistance, strong sealing

03

Anti-impact, no deformation

04

Movement freely

05

reasonable structure

06

Rugged and durable

Product advantages

● Three guarantees are implemented for the sold products within the validity period. For problems caused by other reasons, the factory actively assists users to solve the problems to ensure that the products are put into operation in time and minimize the loss.

Major equipment installation, commissioning, technology personally led the door-to-door service to solve the user's various problems.

● After the company's products arrive at your place, the technical staff will be responsible for assisting in the installation and debugging work.

● Actively cooperate with users to do a good job in the field operation and maintenance management of products, and can provide users with spare parts and accessories of our products at cost price at any time.

● Adhere to the principle of quality first and user first, and listen to the call of users at any time. When on-site service is needed, our factory guarantees to give a reply within 24 hours after receiving the user's notice, and reach the scene within 72 hours. The fastest transportation arrived within 32 hours.

● If the equipment has quality problems within the scope of maintenance, the company shall be responsible for free maintenance and arrive or reply within 2-5 hours after receiving the user's phone call.

Scope of application

The structure and layout of the protective cover of the wall-type machine tool shall be reasonably designed so that the human body cannot directly enter the dangerous area. When the protective cover of the vertical machining center is used to prevent injuries caused by the accidental passage of fingertips, the opening width of the universal protective cover: the diameter and the short axis size of the side length or oval hole shall be less than 6.5mm, and the safe distance of the guide rail protective cover of the machine tool shall be not less than 35mm. The stainless steel plate protective cover plays an effective protective role in preventing chips and other sharp things from entering the guide rail. Certain structural measures and suitable scraping plates can also effectively reduce the penetration of coolant. It has two materials, cold-rolled steel plate and stainless steel plate, with a thickness ranging from 1.5mm to 5mm. Users can choose according to their requirements. The special surface polishing of the steel plate selected by our company will make it appreciate in value. We can provide the corresponding guide rail protection type (horizontal, vertical, inclined, horizontal) for all types of machine tools.

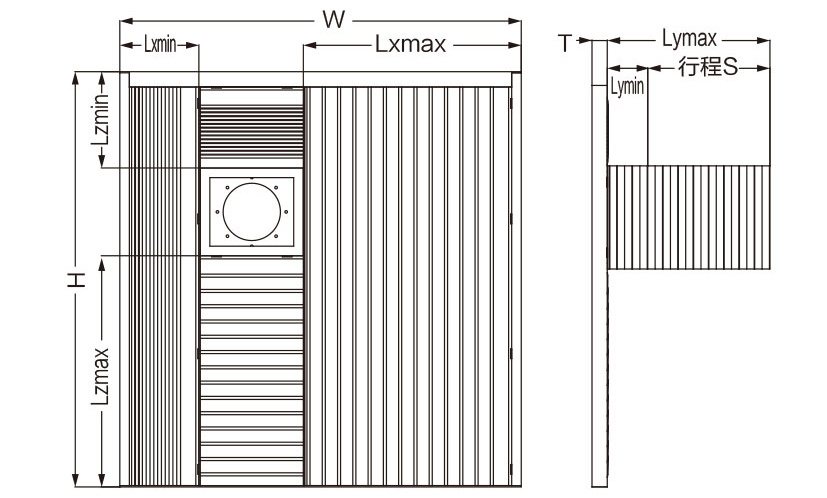

Wall-type protective cover ordering parameter table and receipt

| Code | Parameter Name | Parameter Value | Test results (to be filled by our company) | Remarks | Description |

| Lxmax | X-axis maximum stretch | Operating range of the machine (required | |||

| Lxmin | X-axis minimum compression | ||||

| Lymax | Y-axis maximum stretch | ||||

| Lymin | Y-axis minimum compression | ||||

| Lzmax | Maximum Z-axis stretch | ||||

| Lzmin | Z-axis minimum compression | ||||

| S | Shield travel (X/Y/Z) | Maximum stroke of the machine (optional | |||

| W | Beam width | Required | |||

| H | Height of column | Required | |||

| T | Beam/column thickness | ≥ 70mm (required) | |||

| Optional accessories | Optional | ||||

| Material of protective cover | Material/surface treatment (optional) | ||||

| Guide rail model | - | Model or size (attached) | |||

| Machine tool running speed | - | Required | |||

| Installation method | - | Horizontal/Vertical/Other (optional) | |||

| Installation machine model | - | Optional | |||

| Use environment | - | Large amount of debris (optional) | |||

| Ordering Unit | Shipping Address | ||||

| Contact Information | Delivery Method | Air and Land Transportation Urgent Other | |||

● The above data, CAD drawings or three-dimensional drawings of machine tools (.stp / .x-t / .igs and other formats) shall be provided when ordering, and our company can carry out evaluation and design.

● If there are special requirements for ordering universal protective cover, please fill in the remarks column or contact our company directly. If there is no requirement, it will be made according to our standard.

● Detailed drawings shall be provided for the design of wall protective cover

● If the Ordering Party provides a complete wall shield drawing, please specify the key points for attention.

● We will send this order with the product at the time of delivery.

Our company is a professional custom-made protective cover manufacturer, which can provide products that meet the requirements according to different customer needs. If you have any questions, please consult our staff in time.

Previous:

Inquiry

China

China English

English