Anti-static protective cover

Keywords:

Classification:

Details

Product Introduction

Anti-static protective cover product introduction

Fabrication process

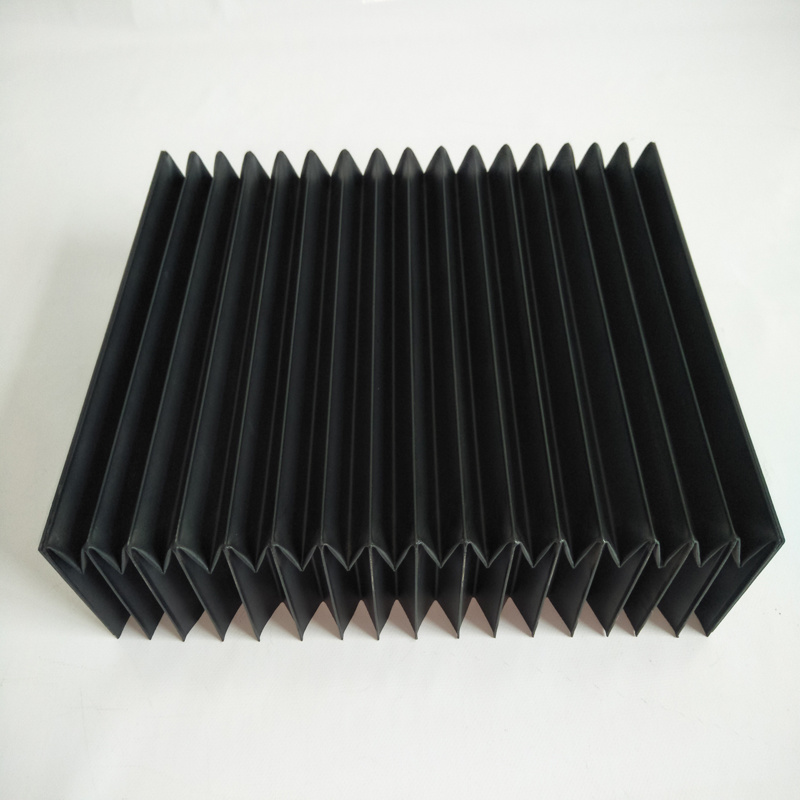

Anti-static organ protective cover manufacturer anti-static organ guide rail protective cover is also called leather tiger.

It is a series of products that can be combined arbitrarily, and its raw materials, appearance, processing methods and sizes can be determined according to the actual situation. One of its basic components is that each hinge is equipped with a PVC skeleton that plays a supporting and stabilizing role. This skeleton can be closely connected to the external hinge material through different processing methods. One is thermal bonding. At a certain temperature, with the help of special flux can make the internal PVC skeleton and the external folding firmly bonded together. If the shield is used in a medium temperature environment, you can choose this way. This kind of thermal bonding shield does not need to maintain it at all, and is waterproof, dustproof, oil-resistant and acid-resistant. The other is the sewing method, which is used in high temperature working environment.

Product category

The anti-static protective cover is sewn with a special thread, which is strong and durable even under extreme loads. The PVC skeleton is fixed on each fold by sewing to reinforce the stabilizing shield. At the same time, there are a variety of materials for you to choose. The use of internal support material increases the shape stability of the shield, and the direct expression of this stability on the shield is to ensure that the original shape can be restored.

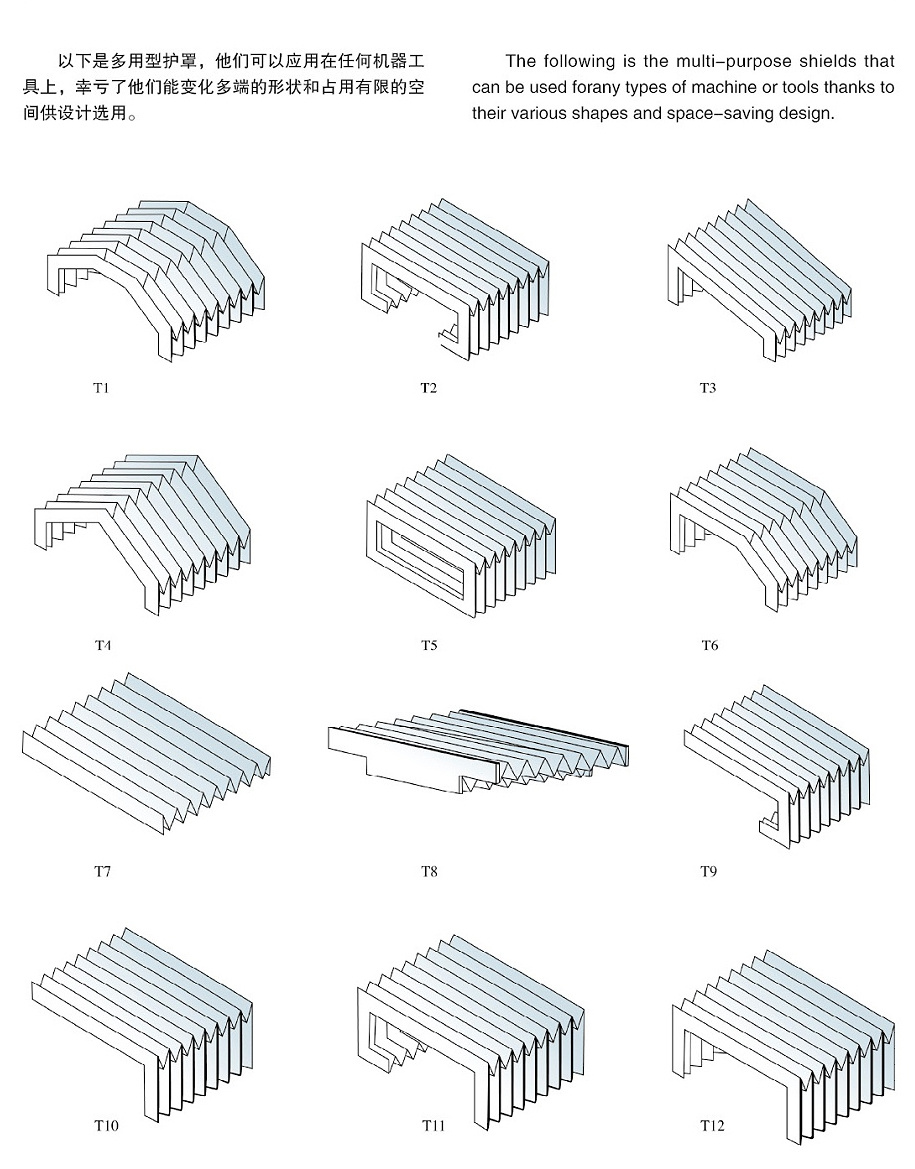

Order requirements fill in this form anti-static organ guide shield style can be customized according to the actual situation of customers.

| Name |

Data |

Name |

Remarks |

| Length after stretching |

|

Outer ring diameter |

User-defined |

| Length after contraction |

|

Inner ring diameter |

|

| Lower connection length |

|

Outer diameter of connection |

|

| Upper connection length |

|

Inner diameter of connection |

|

Product Features

The material of the anti-static protective cover is special anti-static cloth. (Contact customer service to choose the process)

Scope of use (anti-static organ protective cover customized)

With the continuous improvement of machinery and equipment, the requirements of the protection system have also increased accordingly, especially the use of servo motors makes the speed of processing machinery higher and higher, sometimes up to 200 m/min, which requires anti-pulling but light-weight materials. Protection. In addition, the flexible organ guide shield is more and more widely used in the fields of medicine, measurement, automatic control and food technology. These industries require the shield to be dust-proof and non-toxic to food. It is also more and more widely used in the lifting platform of automobile production assembly line.

Characteristics

1. Not afraid of stepping on the foot, hard objects will not deform when colliding, long life, good sealing and light operation.

2. Long stroke and small compression.

3. Coolant resistance, oil resistance, waterproof, acid resistance, anti-grinding wheel foam and iron filings, etc.

4. The speed can reach 200 m/min.

Precautions

(1) Height of standard folding surface: 15mm, 20mm, 30mm, 35mm, 40mm, 45mm, 50mm.

(2) The distance between the guide rail surface of the mechanical equipment and the shield is at least 5 mm and the maximum is 10mm.

(3) When the folding surface of the shield is opened, the size is equal to twice the height of the folding surface.

(4) The thickness of the compressed folding surface is 4mm.

Inquiry

China

China English

English