High temperature resistant lead screw protective cover circular cylinder telescopic type

Keywords:

Classification:

Details

Product Introduction

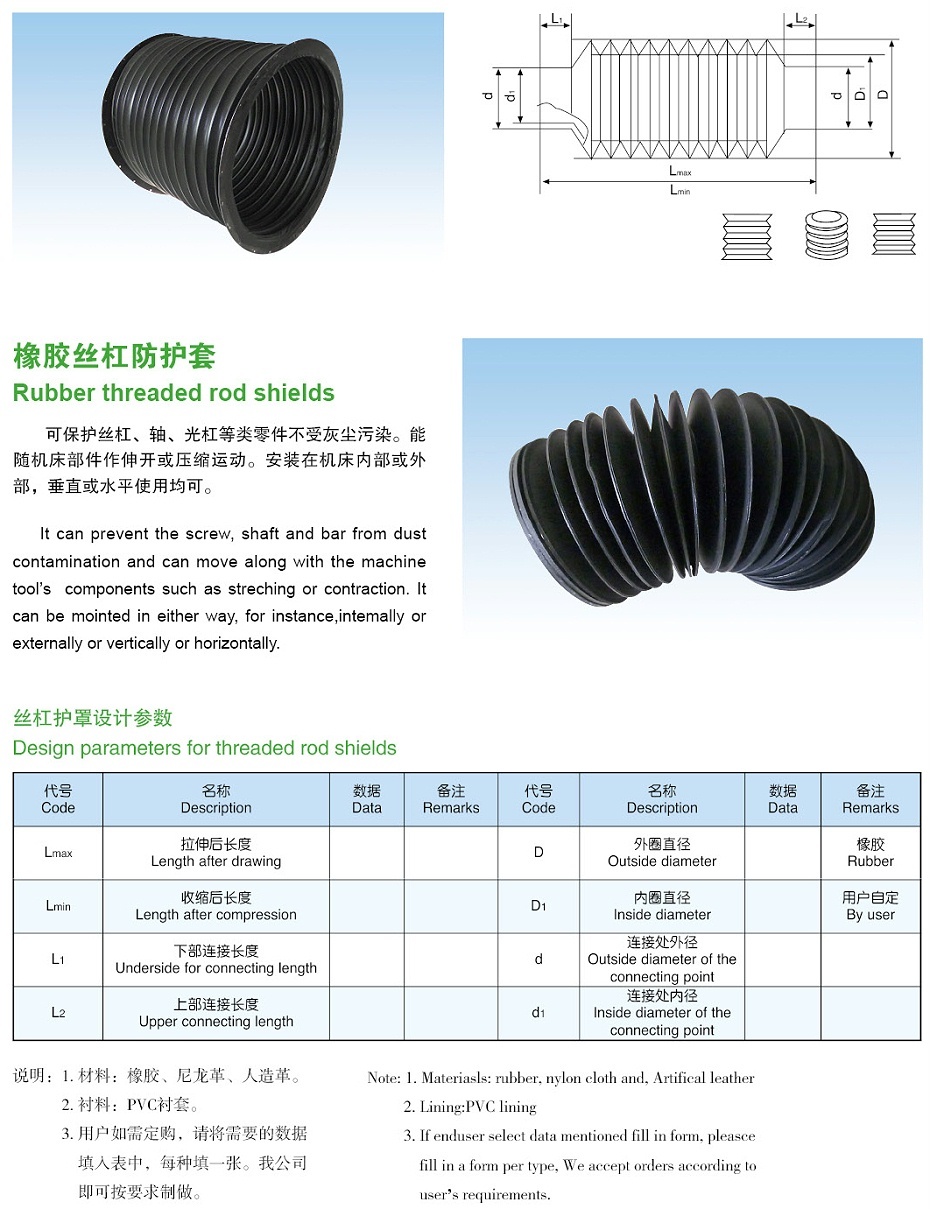

The lead screw protective cover is a kind of machine tool protective cover, also known as the lead screw protective cover, which can effectively protect the lead screw, light bar, shaft, column and other parts from dust and other special pollution and damage.

Process Classification

According to the production process is divided into steel ring support type, sewing type.

According to the shape is divided into cylindrical, tower, square, rectangular, oval, staircase, meniscus, semi-circular and other shapes.

According to the connection mode, it can be divided into (1) two collar (clamp type)(2) two flange (screw type)(3) one flange and one collar. Flanges can be divided into PVC flanges and metal flanges.

Folding steel ring support type

Using a variety of fabrics, supported by a wire ring, made of high-frequency heat-sealing sleeve, fixed outer diameter. Can work normally between high temperature 110 ℃ and low temperature -40 ℃. Effective dustproof, waterproof, anti-oil, anti-emulsion and chemicals, with neat shape, not easy to deformation characteristics, based on its tight, strong, can be used for many mechanical ventilation, dust removal, etc. The required diameter and length can be determined according to the specific requirements of the user.

Folding sewing type

According to the different working environment, there are a variety of materials, first made into a disc by stamping, sewing, adjacent to the two inner edges, two outer edges stitched together, through sewing can achieve a better shape stability and the horizontal direction of the firm. According to the installation method, it can be divided into integral type, zipper type, fastening type, snap type, etc., which brings greater convenience to the installation of users.

Working characteristics

It can be extended or compressed with the components, and can be used vertically or horizontally. In the horizontal position, a plastic or aluminum support ring is used to keep a certain uniform distance between the inner cavity of the shield and the screw rod to extend the service life. When the tensile length is large, a metal ring is added to each compromise to improve the stability of the shield. Use metal flanges for connection or fixing ends, or select the ferrule type.

Baby details

Inquiry

China

China English

English