Organ type protective cover

Keywords:

Classification:

Details

Product Introduction

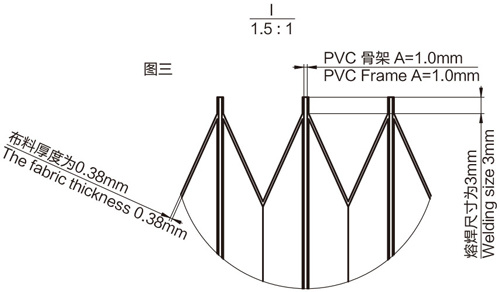

The flexible organ protective cover is made of nylon leather, plastic fabric or synthetic rubber folded, sewn or hot pressed. The organ protective cover is supported by PVC plate, which can be heat-resistant, oil-resistant, coolant-resistant, and the instantaneous contact temperature can reach 2000 ℃, and the insulating support plate is adopted. The travel speed can reach 100 m/min. According to user requirements, the organ protective cover can be equipped with stainless steel sheets in addition to the production of flat bellows, and can also produce round, hexagonal, octagonal, etc.

Product Features

01

Small compression, long stroke, no noise, fast movement, oil resistance

02

Corrosion resistance, hard object collision, no deformation

03

Long life, good sealing, smooth walking

04

Durable, regular shape, beautiful appearance, can be customized

Product advantages

● This kind of shield hard object collision is not deformed, long service life, good sealing and easy operation, etc. The product uses special materials, resistant to coolant, oil and iron filings, and the shield has the advantages of long stroke and small compression.

● There are no metal parts in the flexible organ protective cover, so there is no need to worry about the loose parts of the guide rail protective cover when it works and causes serious damage to the machine.

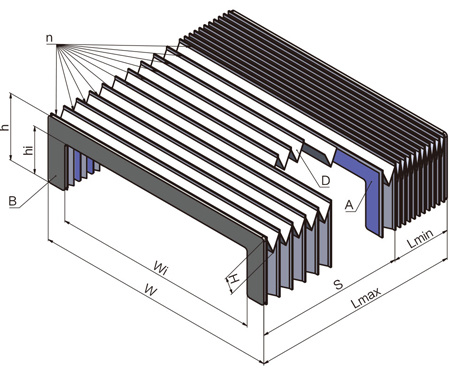

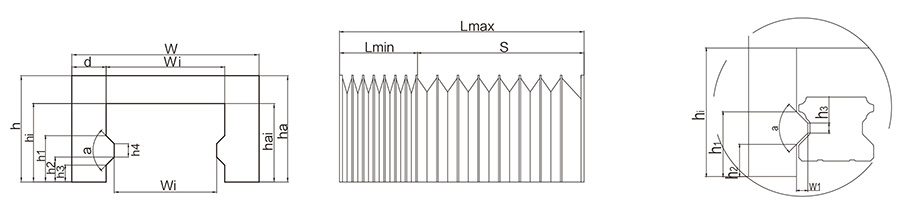

Schematic diagram of technical parameters

Lmax = maximum stretch of the shield

Lmin = minimum compression of the shield

S = stroke length

W = Outer width of shield

Wi = Inner width of shield

h = outer height of protective cover

hi = shield inner height

H = Folding height of the shield

n = number of folds of shield

D = Fabric for protective cover

A = Shield skeleton

B = Flanges at both ends of the shield

H≤ h-hi or H≤(W-Wi)/2 (symmetrical on both sides); unless otherwise specified, the flanges at both ends of the protective cover are made of Q235

Product shape

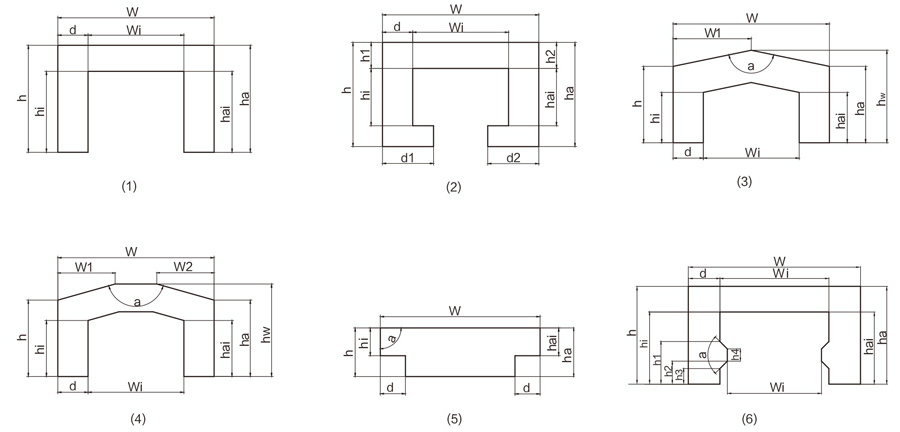

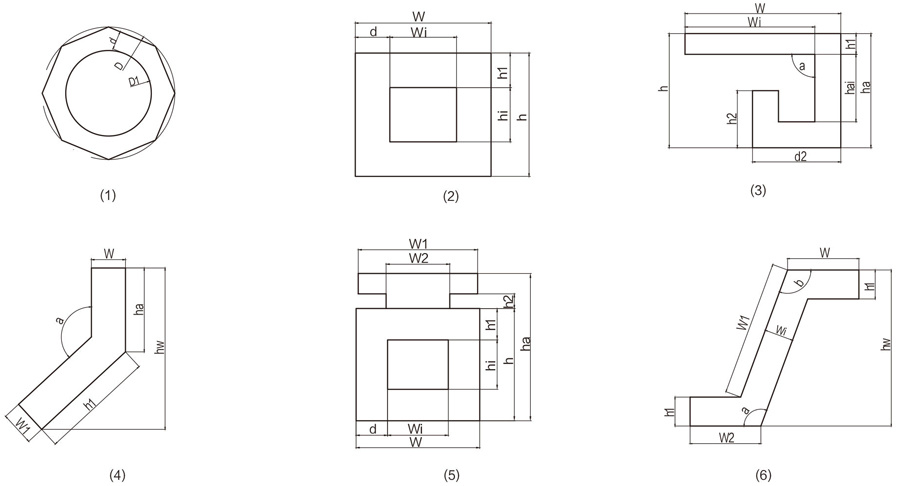

Basic shape:

special-shaped protective cover:

Technical parameter table

|

10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 |

| 100 | 37 | 22 | 19 | 16 | 13 | 13 | 13 | 13 | 13 | 10 |

| 150 | 53 | 31 | 22 | 19 | 16 | 16 | 16 | 13 | 13 | 13 |

| 200 | 68 | 37 | 28 | 22 | 19 | 19 | 16 | 16 | 16 | 13 |

| 250 | 83 | 46 | 34 | 28 | 22 | 22 | 19 | 19 | 16 | 16 |

| 300 | 99 | 53 | 37 | 31 | 25 | 22 | 22 | 19 | 19 | 16 |

| 350 | 114 | 62 | 43 | 34 | 28 | 25 | 22 | 22 | 19 | 19 |

| 400 | 130 | 68 | 50 | 37 | 31 | 28 | 25 | 22 | 22 | 19 |

| 450 | 145 | 77 | 53 | 43 | 34 | 31 | 28 | 25 | 22 | 22 |

| 500 | 160 | 83 | 59 | 46 | 37 | 34 | 31 | 28 | 25 | 22 |

| 550 | 176 | 92 | 65 | 50 | 40 | 37 | 31 | 28 | 28 | 25 |

| 600 | 191 | 99 | 68 | 53 | 43 | 37 | 34 | 31 | 28 | 25 |

| 650 | 207 | 108 | 74 | 59 | 46 | 40 | 37 | 34 | 31 | 28 |

| 700 | 222 | 114 | 80 | 62 | 50 | 43 | 37 | 34 | 31 | 28 |

| 750 | 238 | 123 | 83 | 65 | 53 | 46 | 40 | 37 | 34 | 31 |

| 800 | 253 | 130 | 89 | 68 | 56 | 50 | 43 | 37 | 34 | 31 |

| 850 | 268 | 139 | 96 | 74 | 59 | 50 | 46 | 40 | 37 | 34 |

| 900 | 284 | 145 | 99 | 77 | 62 | 53 | 46 | 43 | 37 | 34 |

| 950 | 300 | 154 | 105 | 80 | 65 | 56 | 50 | 43 | 40 | 37 |

| 1000 | 315 | 160 | 111 | 83 | 68 | 59 | 53 | 46 | 43 | 37 |

| 1500 | 462 | 238 | 150 | 123 | 99 | 83 | 74 | 65 | 59 | 53 |

| 2000 | 622 | 315 | 213 | 160 | 130 | 111 | 96 | 83 | 77 | 68 |

| 2500 | 776 | 391 | 265 | 201 | 160 | 136 | 117 | 105 | 92 | 83 |

| 3000 | 930 | 462 | 315 | 238 | 191 | 160 | 139 | 123 | 111 | 99 |

| 3500 | 1084 | 545 | 367 | 277 | 222 | 188 | 160 | 142 | 127 | 114 |

| 4000 | 1238 | 622 | 419 | 315 | 253 | 213 | 185 | 160 | 145 | 130 |

| 4500 | 1392 | 699 | 462 | 355 | 284 | 238 | 207 | 182 | 160 | 145 |

| 5000 | 1546 | 776 | 521 | 391 | 315 | 265 | 228 | 201 | 179 | 160 |

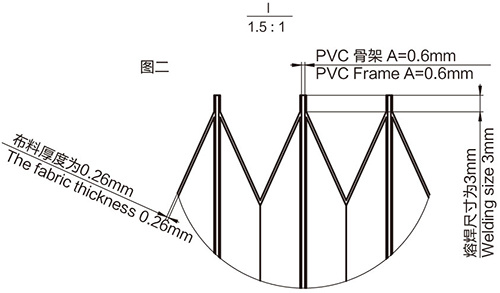

The above data are based on the parameters in Figure 2, are the most value size.

|

10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 |

| 100 | 47 | 27 | 23 | 18 | 15 | 15 | 15 | 15 | 15 | 11 |

| 150 | 67 | 39 | 27 | 23 | 18 | 18 | 18 | 15 | 15 | 15 |

| 200 | 87 | 47 | 35 | 27 | 23 | 23 | 18 | 18 | 18 | 15 |

| 250 | 107 | 59 | 43 | 35 | 27 | 27 | 23 | 23 | 18 | 18 |

| 300 | 127 | 67 | 47 | 39 | 31 | 27 | 27 | 23 | 23 | 18 |

| 350 | 147 | 79 | 55 | 43 | 35 | 31 | 27 | 27 | 23 | 23 |

| 400 | 167 | 87 | 63 | 47 | 39 | 35 | 31 | 27 | 27 | 23 |

| 450 | 187 | 99 | 67 | 55 | 43 | 39 | 35 | 31 | 27 | 27 |

| 500 | 208 | 107 | 75 | 59 | 47 | 43 | 39 | 35 | 31 | 27 |

| 550 | 228 | 119 | 83 | 63 | 51 | 47 | 39 | 35 | 35 | 31 |

| 600 | 248 | 127 | 87 | 67 | 55 | 47 | 43 | 39 | 35 | 31 |

| 650 | 268 | 139 | 95 | 75 | 59 | 51 | 47 | 43 | 39 | 35 |

| 700 | 289 | 147 | 103 | 79 | 63 | 55 | 47 | 43 | 39 | 35 |

| 750 | 309 | 159 | 107 | 83 | 67 | 59 | 51 | 47 | 43 | 39 |

| 800 | 329 | 167 | 115 | 87 | 71 | 63 | 55 | 47 | 43 | 39 |

| 850 | 349 | 179 | 123 | 95 | 75 | 63 | 59 | 51 | 47 | 43 |

| 900 | 369 | 187 | 127 | 99 | 79 | 67 | 59 | 55 | 47 | 43 |

| 950 | 389 | 199 | 135 | 103 | 83 | 71 | 63 | 55 | 51 | 47 |

| 1000 | 410 | 207 | 143 | 107 | 87 | 75 | 67 | 59 | 55 | 47 |

| 1500 | 612 | 309 | 208 | 159 | 127 | 107 | 95 | 83 | 75 | 67 |

| 2000 | 814 | 410 | 277 | 208 | 167 | 143 | 123 | 107 | 95 | 87 |

| 2500 | 1016 | 511 | 346 | 261 | 208 | 176 | 152 | 135 | 119 | 107 |

| 3000 | 1218 | 612 | 410 | 309 | 248 | 208 | 180 | 159 | 143 | 127 |

| 3500 | 1420 | 713 | 479 | 362 | 289 | 245 | 208 | 184 | 164 | 147 |

| 4000 | 1622 | 814 | 548 | 410 | 329 | 277 | 241 | 208 | 187 | 167 |

| 4500 | 1824 | 915 | 612 | 463 | 369 | 309 | 268 | 237 | 208 | 187 |

| 5000 | 2026 | 1016 | 681 | 511 | 410 | 346 | 297 | 260 | 233 | 208 |

Scope of application

Ruiao flexible organ protective cover has been widely used in CNC machine tools, electronic equipment, stone machinery, glass machinery, doors and windows machinery, injection molding machines, manipulators, lifting and transportation equipment, automated warehouses, etc. The flexible organ guide shield has a smooth surface, regular shape and beautiful appearance, which adds infinite color to the overall shape of the machine tool. Therefore, it not only provides practical protection for your machine tool, but also adds more visual beauty to the machine tool, so that the overall value of the machine tool has been improved.

Ordering parameter table and receipt of organ type protective cover

| Parameter Code | Parameter Name | Parameter Value | Test results (to be filled by our company) | Remarks | Description |

| Lmax | Maximum shield stretch | Operating range of the machine (required) | |||

| Lmin | Shield Minimum Stretch | ||||

| S | Protective cover stroke | Maximum stroke of the machine (optional) | |||

| W | Outer width of protective cover | Required | |||

| Wi | Inner width of protective cover | Required | |||

| h | Outer height of protective cover | Required | |||

| h1 | Shield inner height | Required | |||

| H | Protective cover folding height | Range: 10mm-55mm (optional) | |||

| B | Connecting flange | Material/surface treatment (optional) | |||

| Fire protection requirements | Whether | Whether | Optional | ||

| Guide rail model | - | Model or size (attached) | |||

| Machine tool running speed | - | Required | |||

| Installation method | - | Horizontal/Vertical/Other (optional) | |||

| Installation machine model | - | Optional | |||

| Use of the environment | - | Large amount of debris (optional) | |||

| Ordering Unit | Shipping Address | ||||

| Contact Information | Delivery Method | Air and Land Transportation Urgent Other | |||

● The above data, CAD drawings or three-dimensional drawings of machine tools (.stp / .x-t / .igs and other formats) shall be provided when ordering, and our company can carry out evaluation and design.

● If there are special requirements for ordering organ protective cover, please fill in the remarks column or contact our company directly. If there is no requirement, it will be made according to our standard.

● Detailed drawings shall be provided for the design of some guide rails

● If the Ordering Party provides a complete drawing of the protective cover of the flexible organ, please indicate whether there is a margin between the protective cover and the guide rail.

● We will send this order with the product at the time of delivery.

Previous:

Next:

Inquiry

China

China English

English